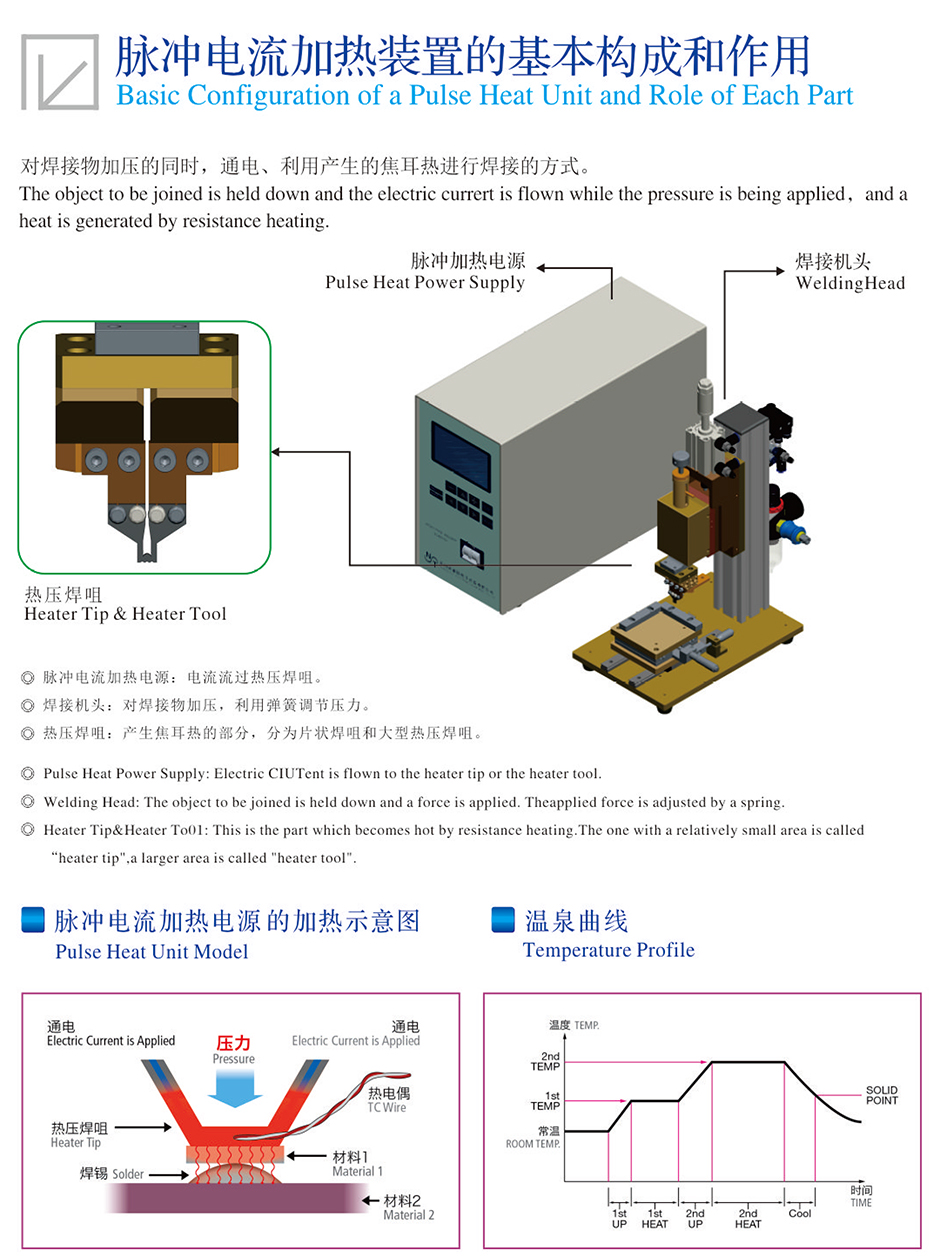

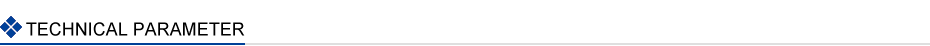

1. DC output. The welding current is pulsating DC (and the waviness is small), and there is no AC zero crossing discontinuous heating of workpiece. The heat is concentrated, which improves the welding thermal efficiency. It is especially suitable for the welding of non-ferrous metal materials and some difficult to weld materials. The welding process is stable and the welding quality is significantly improved. At the same time, the electrode life is prolonged.

2. It is controlled by MCU and has temperature monitoring function.

3. The inverter bridge adopts soft switch technology to reduce switching loss and electromagnetic interference.

4. It has fault diagnosis and alarm functions such as temperature abnormality, monitoring value over limit, network voltage over limit, overheating, etc.

5. The inverter bridge will turn off automatically in case of abnormal current and enhance the system protection.

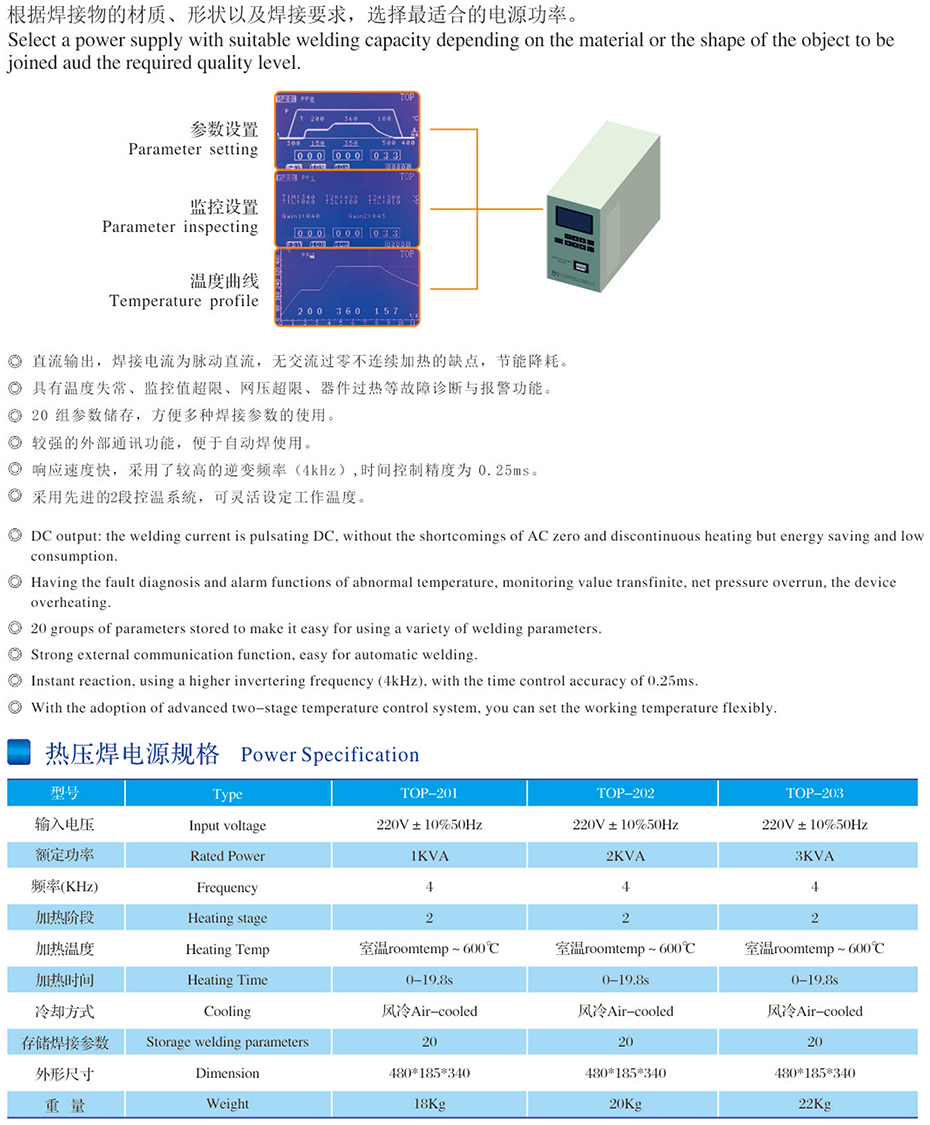

6. Two stage heating setting, with temperature slow rise and slow drop function, and time wide range setting (0-250ms), suitable for complex welding process.

7. 20 sets of parameters are stored for convenient use of various welding varieties.

8. 240X128 LCD display with multiple contents.

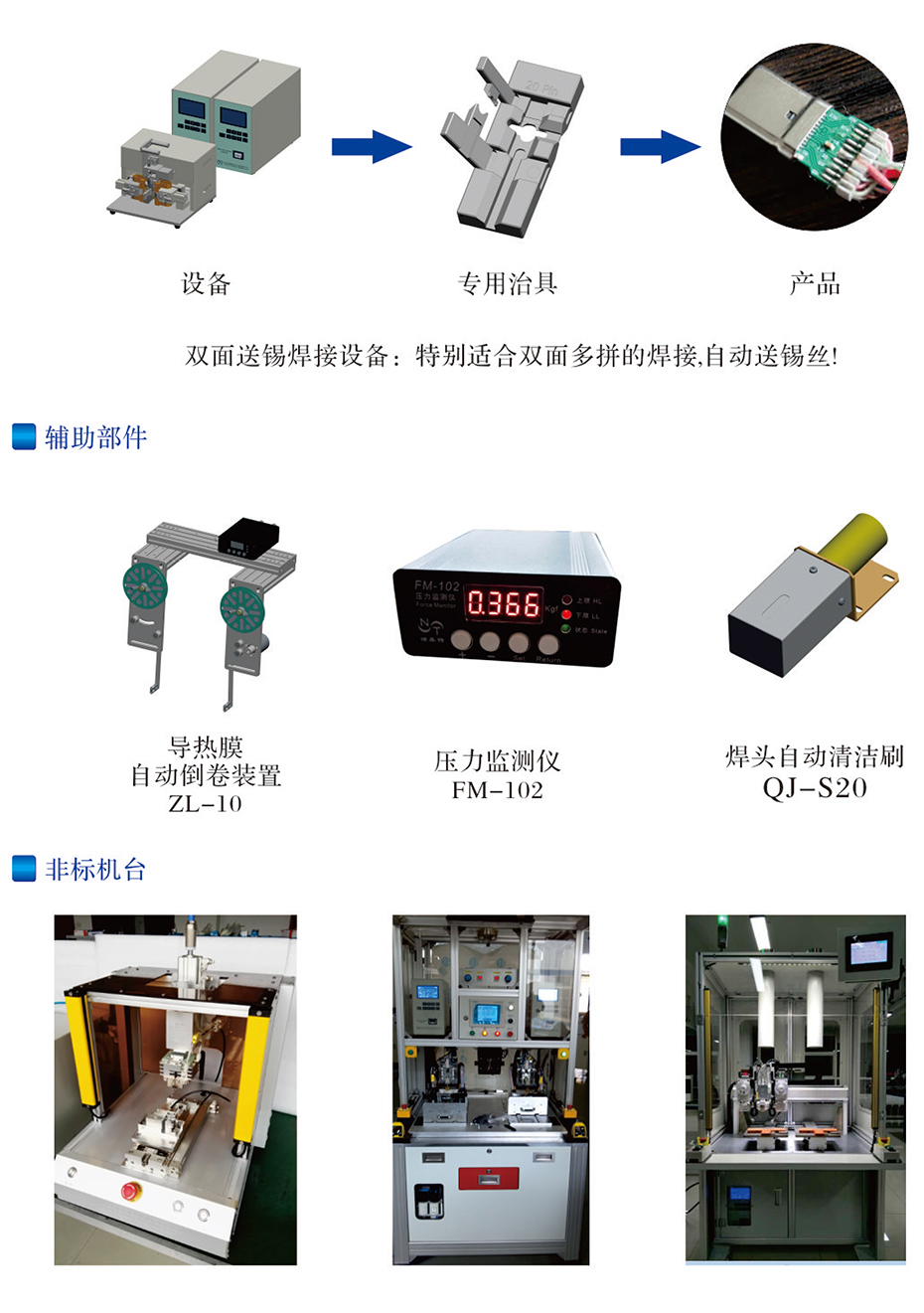

9. Strong external communication function: welding end, fault, counting signal, RS-232 data communication port, convenient for automatic welding.

10. EEPROM is used for data storage, without battery life problems.

11 fast response. Due to the high inverter frequency (4kHz), the power on time control cycle is 0.25ms, which is 80 times higher than the normal 20ms of AC welding machine, and the control accuracy is significantly improved. Compared with the capacitor energy storage welding machine, it does not need charge and discharge, and its controllability is obviously enhanced. It is especially suitable for the welding of precision parts and high-quality, high-precision and high-speed welding.

12. Advanced temperature control system is adopted, which can flexibly set the heating state of each section, and control the temperature, time and other parameters with high precision.

13. The temperature rises rapidly and stably, and the local instantaneous heating mode can well inhibit the thermal impact on the surrounding components.

14. Display the temperature of each stage.

15. The closed-loop online feedback control of thermocouple improves the accuracy of temperature control.

Taobao1

Taobao1 Taobao2

Taobao2 Alibaba Wuxi

Alibaba Wuxi Shenzhen Alibaba

Shenzhen Alibaba

English

English Chinese

Chinese